Temperature-controlled logistics is a broad topic, on which an entire encyclopedia can be written.

In this article, I want to convey to scientists and / or those who do not have enough knowledge on the subject, in a very general but useful way, the way this industry operates, in order to provide you with basic tools in proper conduct with shipping companies and especially so you know what logistics solutions are right for you .

Before I start with the guide, I want to tell you two true stories (out of hundreds) that convinced me to write this guide.

Story 1

Anna (pseudonym), is a principal investigator at one of the universities and by virtue of her position, is responsible for hundreds of laboratory experiments performed by her students.

Monday morning, Anna asks the shipping company to make a refrigerated delivery (2-8C), a representative of the shipping company asks if to provide a temperature recorder at an additional cost, Anna answers in the negative.

The next morning, the courier arrives to pick up the shipment with a case in it at the right temperature suitable for refrigerated delivery, loads it on the vehicle and travels directly to the airport, delivers it to the cargo terminal and after 72 hours the package is delivered to the destination country.

The recipient opens the case and informs Anna that the temperature inside the case is “not cold enough”.

Immediately Anna calls the shipping company and angrily reports that the shipment arrived at the customer not at the correct temperature, the shipping company representative checks the shipping data and informs Anna that it is not possible to check the temperature issue or prove that the temperature exceeded, because there was no temperature recorder Prepared according to the manufacturer’s requirements at the required temperature.

Later in the conversation, Anna says that the shipment contained material that her students had been working on for two months and included a reagent that cost thousands of dollars.

So what did we have here?

· A shipment that one side says has exceeded the temperature but cannot be tested or proven.

A shipment that contains expensive materials that may have been destroyed due to a temperature deviation.

Story 2

Biomagic (pseudonym), is a young company that develops an oncology drug.

The company employs 4 scientists who previously worked together at one of the universities.

Most preclinical work is performed in external laboratories, so the company performs a significant number of deliveries, relative to its size.

One of the scientists asked to send samples to a laboratory abroad, the shipment is on dry ice and as always, he calls the courier express company (FedEx / DHL), so that they can come and collect the shipment.

The courier arrives at the company and the investigator hands him a styrofoam case filled with dry ice containing the expensive material intended for active testing.

The courier arrives at Ben Gurion Airport, the package goes through a security process and takes off for the flight, the shipment arrives at a destination in Europe and waits for a continuation flight, but since there is a load on flights due to the Corona plague, the shipment waits at the stopover for 24 hours. Customs with delay – because the country is in quarantine, and the shipment was delivered 5 days later, of course there was no more dry ice in the package and the contents were thrown in the trash.

Now that I have told these two stories, which are actually two unfortunate incidents of lack of knowledge / understanding in the field of temperature controlled logistics / shipping, we will continue with the guide.

The following guide only applies to temperature-controlled shipments sent by air.

In the guide we will go over the following topics:

1. Packaging solutions

2. Types of service

Official / Emotional Temperature

Packaging Solutions

There are currently three main types of solutions for maintaining the desired temperature:

Active package: is a package with a built-in cooling unit, which operates on rechargeable batteries and / or electricity connection at the transit stations, for an autonomous work capacity package (without electricity connection) of about 130 hours (depending on the manufacturer).

An active case can provide a solution for delivery at temperatures between + 25 ° C and -20 ° C

Passive enclosure: is an enclosure that maintains the temperature using external cooling units (ice creams, gel bags, dry ice, liquid nitrogen, etc.), with a temperature range between + 25 ° C and 196 ° C

Thermal blankets: A product that insulates the shipment from weather conditions, intended for large shipments that are shipped at a temperature between + 25 ° C and + 2 ° C, widely used in shipments of generic drugs.

When to use an active or passive package?

Large shipments: For shipment the size of a pallet (up to 1.50 meters high – depending on the container supplier), there are passive and active solutions, the decision which solution to use depends on the shipment destination (suitable storage options), value of goods, route duration, agent in the destination country. (If necessary), the stability of the material shipped, the weather in the destination country (to understand how the weather affects the decision which solution to use, you can read the second article I wrote on the subject) and of course price / cost.

Small deliveries: For small deliveries up to 96 liters volume (45.7 cm length, width and height), passive cases are most often used.

Passive enclosures have the ability to maintain the required temperature for up to over 120 hours.

To better understand how the passive packages work and what solution is right for your shipments, we will go through all the existing situations and the proposed solutions

Liquid Nitrogen Shipments (-196 ° C): For these shipments, use special containers soaked in liquid nitrogen, with stability depending on the size of the container, usually maintaining the temperature for at least 10 days.

Delivery at a temperature of -70 ° C (the usual range is between -60 ° C and -80 ° C): For these deliveries, dry ice is used as a cooling unit.

Dry ice is defined as a dangerous substance to fly, so the amount of dry ice that can be flown is limited, which means that if there are many shipments of dry ice that need to board the same flight (beyond the allowable amount), some will not board the plane.

The dry ice has a freezing capacity depending on the amount of ice inside the package and can reach beyond 100 hours.

Deliveries at a temperature of -20 ° C (± 5 ° C)

The usual (and best) solution for deliveries at a temperature of -20 ° C, are passive packages with ice creams that contain a substance that changes its shape according to temperature (Phase Change Material) and upgraded panels of the VIP type (Vacuum insulated panel), these packages come in sizes between 4L and 240L

There is a widespread opinion that dry ice can be used for deliveries at a temperature of 20 ° C and indeed it is possible. However, there is a real difficulty in determining the amount of dry ice required to maintain and regulate the desired temperature.

Deliveries at a temperature of + 5 ° C (± 3 ° C and deliveries at a temperature of + 20 ° C (± 5 ° C)

The existing solutions for deliveries in these temperature ranges are the same.

There is a wide range of solutions, ranging in size from 4L to 240L (Full Pallet) from different manufacturers,

The solutions are divided into two types

Main:

Disposable cases – These cases are usually based on Gel Packs with a stability of up to 96 hours (depending on the size of the case and the manufacturer). PCM-based disposable packages are also available

The advantage of disposable packages is mainly a relatively low cost for a reusable package, and there is no need to return it to the sender at the end of the trip.

Reusable enclosures – These enclosures are PCM-type glaciers with a long stability of up to 144 hours (depending on the size of the enclosure and the manufacturer) .

The main advantage of reusable packages is mainly the quality of stability and maintaining the required temperature over days.

Types of service

Now that we know what type of case we will use in shipping, we will move on to choosing the type of service we are interested in using.

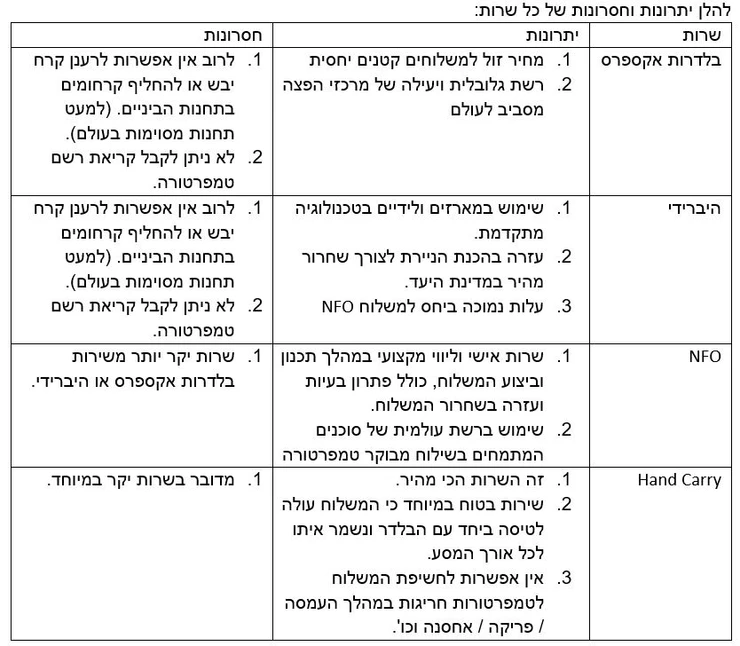

As of this writing, there are four types of service for international temperature controlled shipments made by air.

Delivery via express courier companies (FedEx, DHL, UPS, TNT, etc.): In these shipments, it is the customer’s responsibility to pack the shipment and the courier company will deliver the shipment as it is to the recipient of the destination.

2. Delivery by NFO (Next Flight Out) service: These shipments are made by specialized shipping companies, these companies provide full service from start to finish (including delivery of a package and lead at the required temperature) and use the fastest routes possible to reach the destination port, based on flight service Commercial (passenger planes) and cargo flights, accompanied by an agent specializing in temperature-controlled shipments in the destination country that handles the release of the shipment and its delivery to the final recipient.

3. Hybrid shipment (Hybrid): is a shipment that combines the equipment of the local forwarder and the international flight / shipping in cooperation with courier companies.

In this type of service, the local shipping company delivers the package and the temperature recorder, including collecting the shipment, consuming it, performing customs processes and handing it over to a courier company that flies it to the destination country including the customs clearance process at the destination and delivery to the recipient.

4. Hand Carry Delivery: In this service, a representative from the shipping company boardes a commercial passenger flight (as a passenger for everything) and manually carries the delivery in a controlled package and temperature recorder, and personally delivers the delivery to the final recipient at the destination.

Formal / emotional temperature

The most common temperature recorder on the market is an electronic recorder inserted into the chassis, attached to the product and measures the temperature every pre-set period of time.

Temperature recorder that incorporates a GPS component, which connects to a cellular or GPS network and transmits the location of the package when it is on the ground (some have the option to provide on-line temperature data)

A temperature recorder combined with a humidity recorder and / or light sensor, is a recorder that, in addition to the temperature jump, is able to alert you to the opening of the package (using the light sensor) and recorders that also include a humidity recorder.

Temperature recorder with external sensor (Probe), this type of recorder is located outside the package when the temperature sensor is adjacent to the product itself inside the case and is connected via a cable to the recorder, so you can know the temperature data without having to open the case. This type of register is mostly common in the use of liquid nitrogen tanks but exists for all temperature ranges.

Temperature Sensation : is a tiny device that warns of temperature deviation.

This device does not record a temperature and can not display the temperature range or anomalies, but only alert whether the temperature has exceeded (yes or no) most often by changing the color of the monitor.

These sensors are mainly used in shipments of generic drugs, when the stability data of the product are known and the temperature range is less important but the deviation itself.

When is it recommended or when is it mandatory to use a temperature sensor / sensor?

Obligation to use:

According to the Ministry of Health’s 130 procedure ” Adequate distribution conditions for humane veterinary preparations ” which is a derivative of the European Good Distribution Practice Guide 2013 / C 343/01 and according to the Ministry of Health’s 126 procedure ” Storage and transport conditions of Preparations “:

Each preparation must be left at a temperature along the entire length of the supply chain.

In addition, drug development companies must also monitor the delivery temperature of the preparations throughout the clinical study.

Any shipment containing a product that is sensitive to temperature (blood samples, biopsies, reagents, solvents, etc.) is recommended .